Planner

Module

Synchronise rolling stock schedule, terminal and vessel operations to maximise efficiency

Maximise throughput

Simultaneously optimise rail, terminal and vessel operations to minimise demurrage and maximise throughput

Model complex networks

Model large and complex networks with many producers, terminals and rail haulage providers

Optimal rail plans

Generate optimal rail plans to cycle level detail for every rail journey for every rail unit in your planning horizon

Bringing Innovation to Rail Supply Chain Planning

The RACE Planner module is a mathematical optimisation tool for planning complex rail based supply chains to maximise throughput and asset utilisation for a range of supply chain stakeholders.

Haulage Providers

For train operators providing haulage services to primary producers

Track Owners

For track owners contracting rail access to primary producers and rail haulage providers

Coordinators

For independent entities that coordinate the combined operations of all rail participants in a common supply chain

Integrated Producers

For vertically integrated producers who own and operate the entire supply chain

Terminal Operators

For operators of bulk terminals servicing a range of producers connected with large complex bulk haulage rail networks

Primary Producers

For primary producers who contract rail haulage providers, track owners and terminal operators to transport bulk commodities

Maximise throughput and fleet utilisation

Ensure that throughput and fleet utilisation are simultaneously maximised for inbound operations.

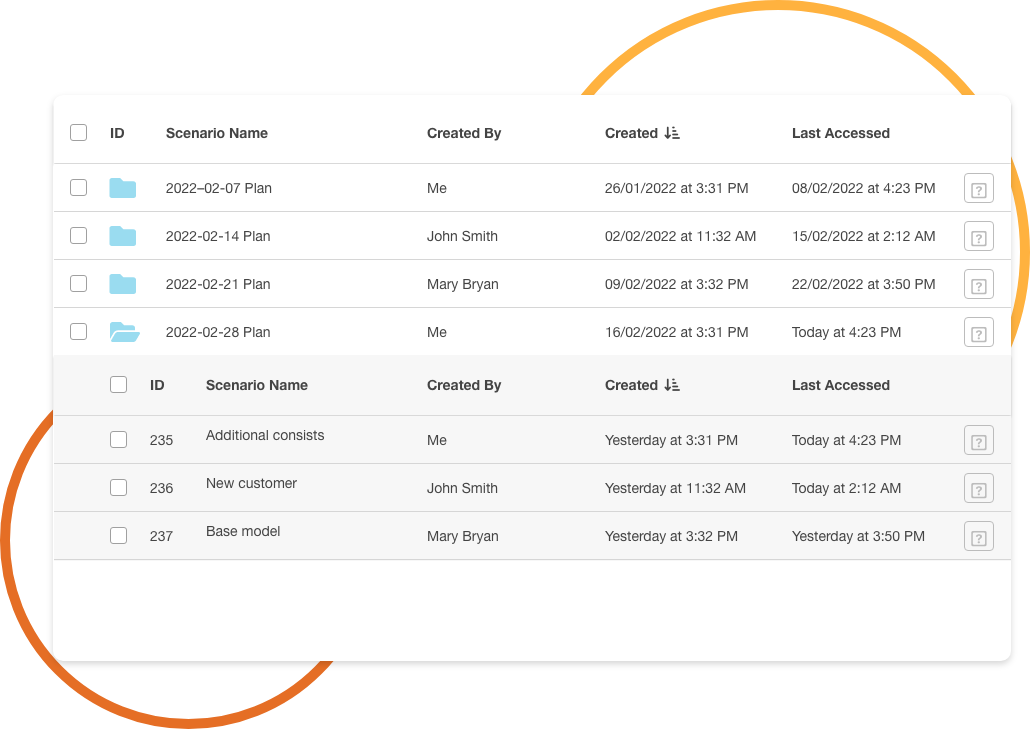

Flexible Scenario Planning

Rapidly run scenarios to examine the impact of:

- Dedicating Fleets

- Supply Chain Maintenance Conditions

- Alternate Operating Regimes

- Different Demand Mixes

- Alternate consist maintenance strategies on fleet efficiency

Model Large and Complex Networks

RACE can model large and complex networks which can include multiple load points and terminals (stockpile or cargo assembly operations), different access controlled track networks, with many haulage providers operating multiple rail fleets with different contracting arrangements.

Generate optimal rail plans to cycle level detail

RACE produces rail plans to the cycle level of detail for every individual rail unit in each fleet for all haulage providers in your model. Cycles may traverse multiple access controlled and run when ready track geographies.

Model Fixed and Flexible Maintenance

RACE can model fixed and flexible maintenance on both the track network and the rail fleet to minimise their impact on throughput.