A holistic approach to rail maintenance planning

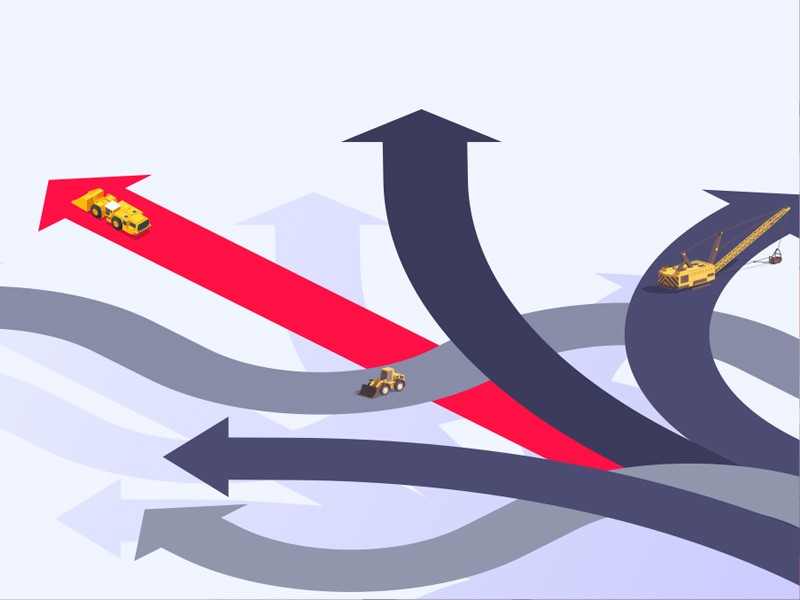

Bulk rail planning teams are constantly challenged by the complexities associated with maintaining a safe, robust network while servicing multiple stakeholders. The dynamic rail planning environment consists of many competing or unpredictable variables such as crew scheduling, rolling stock availability, weather, customer production issues and planned and unplanned maintenance activities.

Maintenance is a critical component of network safety and reliability, but if not planned properly, it can hinder productivity unnecessarily. Understanding the impacts on network throughput and contract serviceability while meeting maintenance objectives is incredibly complex and time-consuming, especially when done manually.

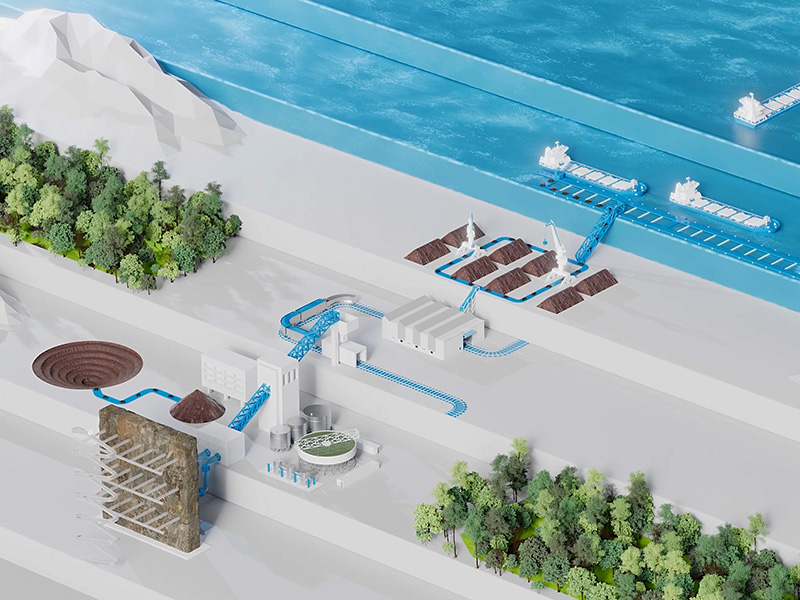

RACE, Polymathian's award-winning bulk rail optimisation software, helps planning teams ensure network maintenance is effectively scheduled by incorporating it into the optimised train service planning process. By creating a holistic planning and scheduling practice, planners can minimise the impact that maintenance activities have on the network.

With RACE’s support, planners can consider maintenance scenarios, such as:

- What if planned maintenance on a particular branch line creates an unavoidable chokepoint within the network?

- What impact will this maintenance event have on the production profile of each producer?

- How does the network serve contractual demand and still meet its overall maintenance requirements?

RACE allows network operators to manage complex maintenance requirements by applying sophisticated industrial mathematics techniques to produce optimal rail schedules. With a click of a button, RACE enables planning teams to rapidly test various scenarios to gain insights into the optimal time to schedule track maintenance. What would have taken days to plan manually can now be done optimally within minutes.

Types of Maintenance Modelling

Floating or flexible track maintenance modelling

RACE can model track maintenance that can "float" in time, i.e., maintenance whose timing is scheduled at the same time as train services.

Floating or flexible above rail maintenance or rail unit-specified maintenance modelling

RACE is capable of modelling "floating" above rail maintenance. In this scenario, revenue and maintenance services are scheduled with the same priority so that it can explore conforming to maintenance constraints without sacrificing throughput.

Modelling "system shutdowns"

When rail networks require significant or extended periods of maintenance activities, RACE can model these "system shutdowns" to allow for rail units to be stowed around the network, in allowable geographies, with sufficient buffer time on either side of the maintenance events.

Conclusion

Rail planning teams are showing a promising uplift in productivity compared to their previous planning process, where maintenance was scheduled independently of demand. By including maintenance in the planning and scheduling optimisation process, planners are unlocking operational efficiencies that create harmony and synchronisation across business units: this alignment and integration results in higher quality plans that minimise the impact of maintenance activities on network throughput.

For more information, or to book a demo, contact us today.