Dynamic Decision Support in Mine Planning

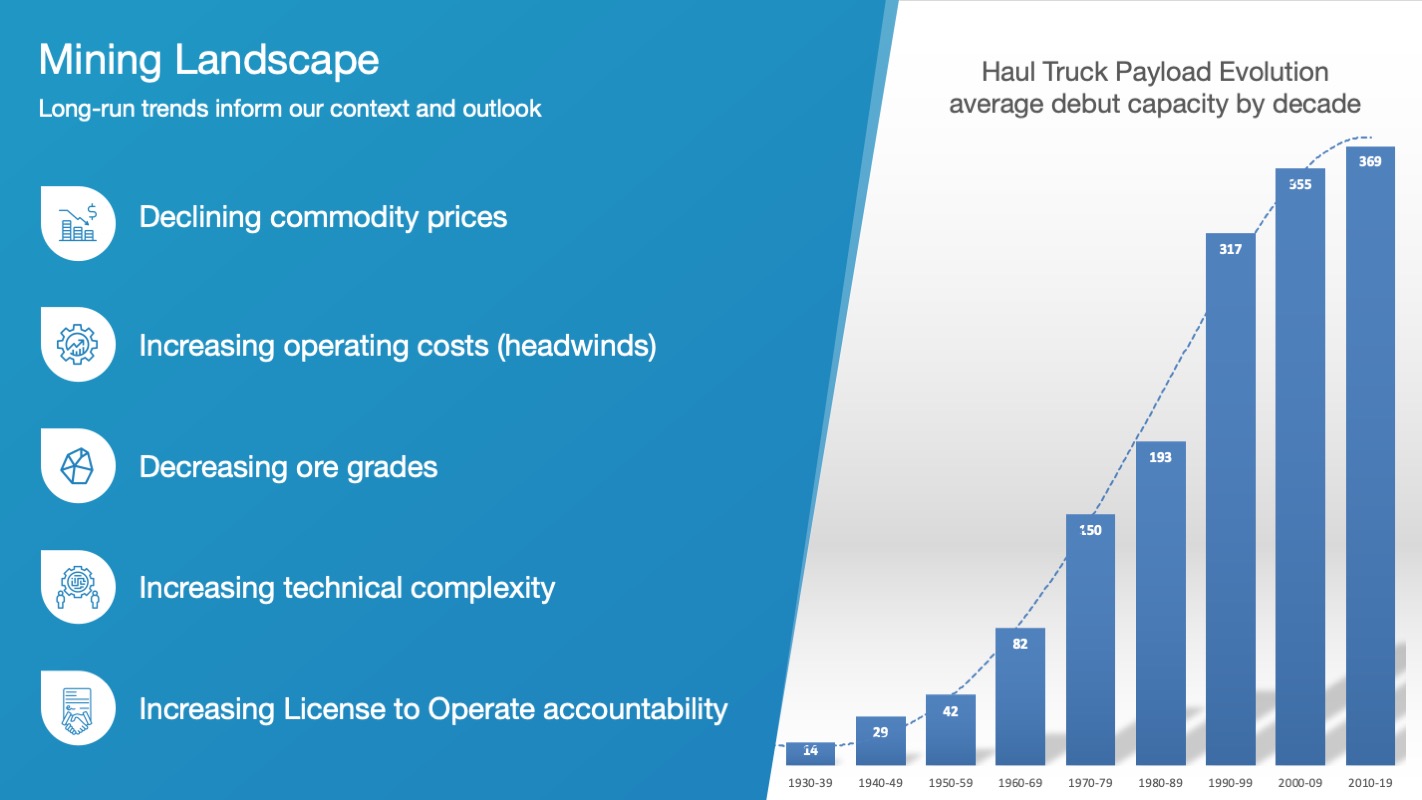

Over the last century of mining history, the key to success and survival – setting aside the quality of the orebody for a moment - was scale. Operators kept or improved their competitive position by moving more material using larger equipment with less people and those who did not lost their competitive advantage. Another thing miners know is next year’s ore will be a little bit deeper, or a little bit further away, or a little bit lower grade, or harder to process, or some combination of these factors.

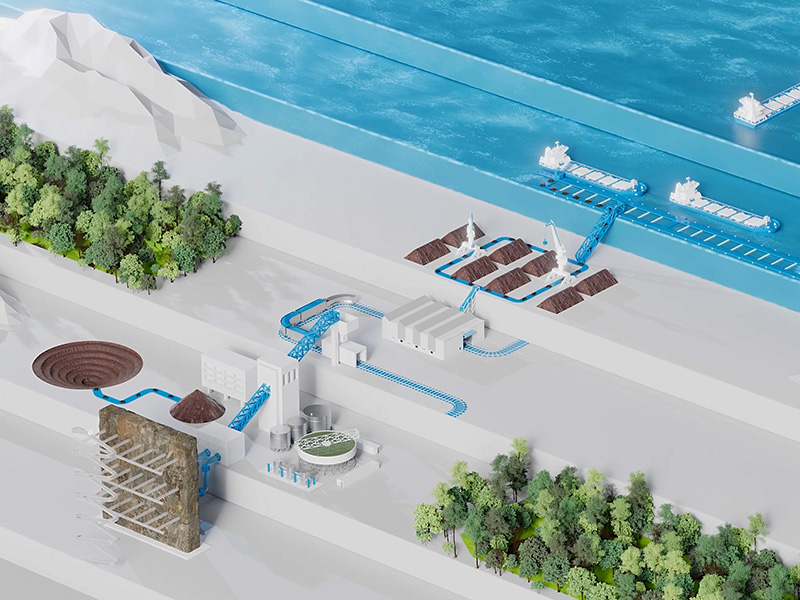

Against these input headwinds the industry was helped along by the progressive scaling-up of engineered equipment. Upsizing gave the industry a productivity boost every few years, whether it was haul trucks and rope shovels, or draglines and longwalls, or crushers and cyclones, or ship loaders and cargo vessels. That progression saw haul truck payload capacity grow a hundredfold over a hundred years, from less than five tonnes to nearly 450.

But the size-engineering era is over. The economic asymptote of engineering scalability was reached nearly a decade ago. The rate of payload capacity growth declined from an average of around 7% per year between 1960 and 2000 to one percent from 2000 to 2010 and half a percent after 2010. In fact, with autonomous operations unit size may scale down in the future.

Does this mean mining’s productivity journey is close to an end and all that remains to be gained are diminishing fractional increments? Not at all. Productivity is a journey to a destination always just beyond the horizon of present knowledge and capability. Although it might seem finished in a classical, mechanical sense, the industry is entering a new era. But like any long journey there are setbacks and interruptions and right now mining is making the awkward transition from the physical to the digital, from the mechanical to the mathematical.

So, does this mean data science will define mining’s future? Not exactly. Digital and data alone are not the answer. Digital is how the answer is packaged and delivered, but it is not the answer. Optimising performance in a digital age is still about one core element - how to make better decisions, faster.

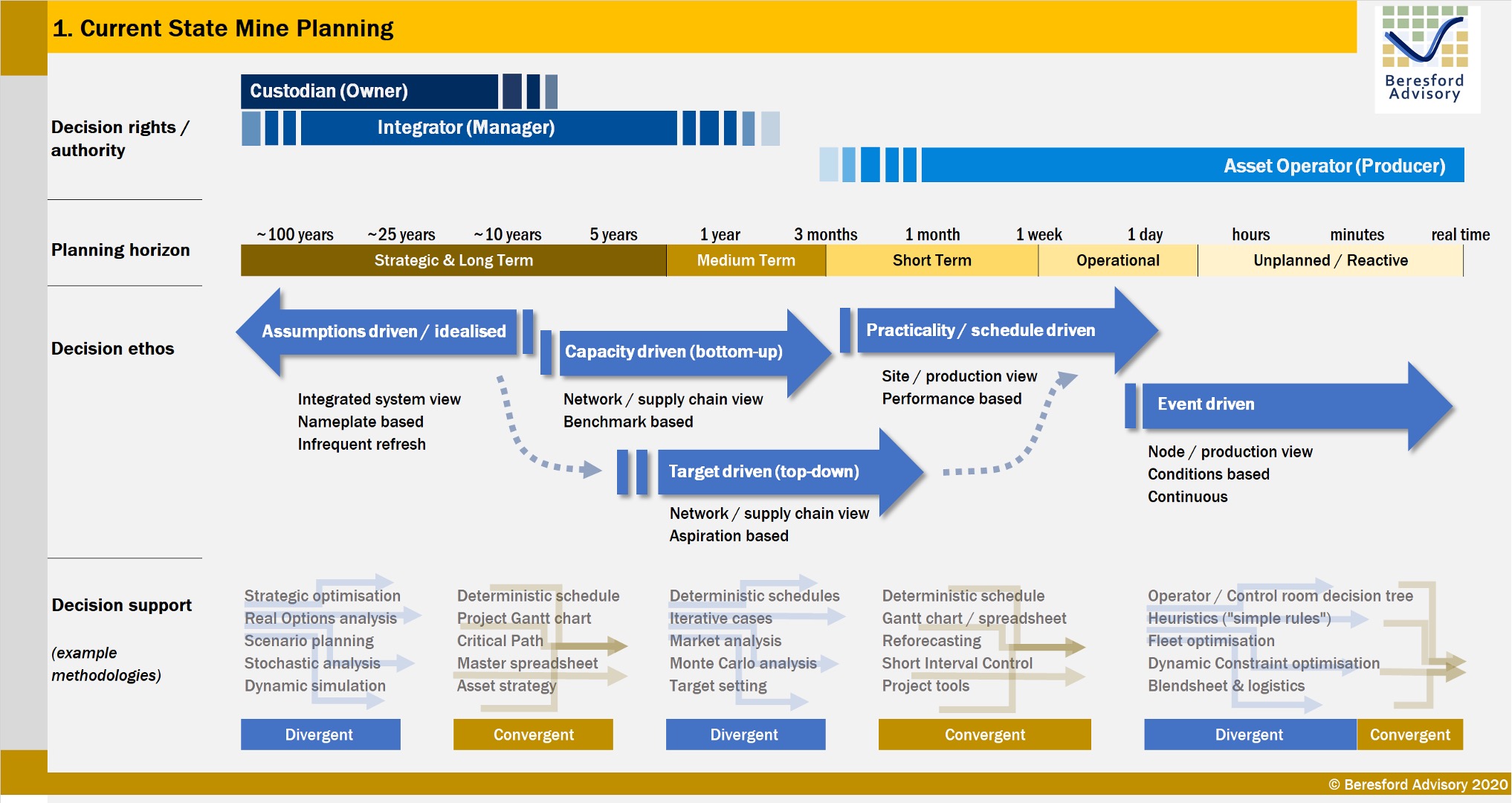

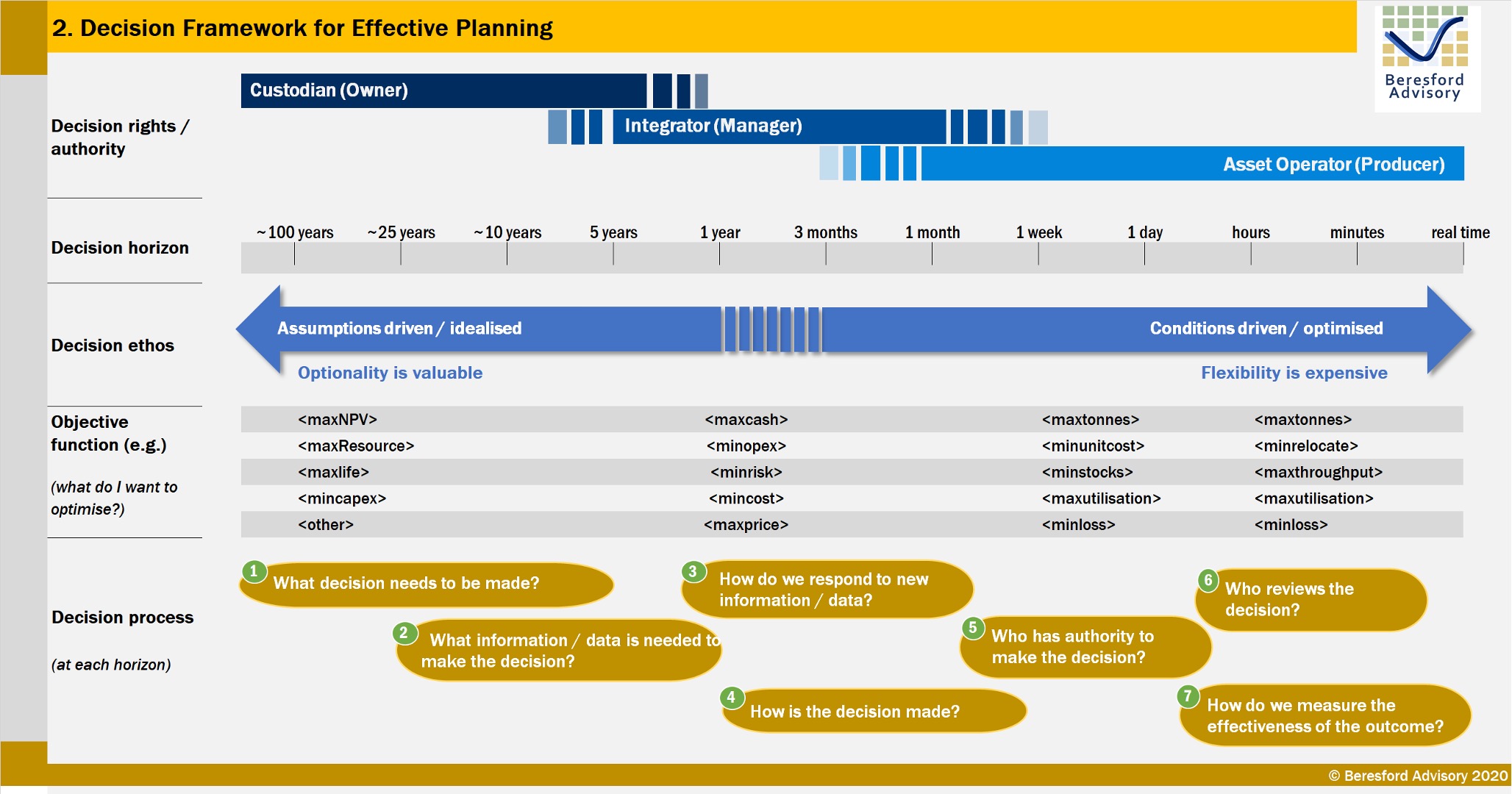

This diagram represents the conventional state of mine planning and decision-making. A few key points are relevant:

- Planning scope, horizons and organisational structures reflect the capacity and limitations of technical software from thirty+ years ago. Back then, mining was at the forefront of mathematical solver development. Strategic optimisation, geostatistical analysis, advanced modelling and simulation – all these launched mining into the computer age by unlocking new value while reducing investment and operating risk.

- Those long-range strategic decisions were made in an assumptions-dominant framework. Yet mines operate to conditions, not assumptions. Conditions change - randomly, dynamically and constantly. But due to the constraints of computing power and solver capability, planners and decision-makers used deterministic tools, simple heuristics, spreadsheets, Gantt charts and mud-maps. At best these gave proxies of value.

- Planning horizons and decision rights may have gaps or confusing overlaps. There may be several plans in place at any time, many with conflicting objectives, incentives and performance metrics. Hence the roles, rights and responsibilities of owner, manager and operator can become misunderstood or misaligned in the decision-making process.

When an assumptions-driven plan is translated into a deterministic production schedule, the tendency is to focus on the original objective even when the context in which it was created has shifted. This traditional approach can be described as a defensive planning stance because its objective is to defend the plan and budget, often regardless of significant departure from its input assumptions. A defensive planning stance seldom outperforms. Often, it is about narrowing the gap between an aspirational target and what otherwise might have happened.

But what is meant by changes in input assumptions? If the geological model is unchanged, the mine design unchanged, and the budget, targets, equipment metrics, and everything else informing the plan is unchanged, why does the plan need to change?

This is the rubber-meets-road reality check for mine planning. Where assumptions meet real-world conditions, whether at first contact with the orebody, or when new external information appears. And of course, this is and has always been, the operating reality. There is a wealth of new information out there - actual price and exchange rate, actual competitor behaviour, actual weather conditions and forecasts, actual maintenance performance, actual mining conditions, actual labour numbers, and so on. So how does the business decide what to do when the dynamics change? How does the business know if it is responding to genuine signal or reacting to noise? And who makes these decisions?

When the operating context changes significantly, how should the business respond?

- Stay on course, focussed on the budget path?

- Decide to benefit the local node, or a different decision for the network?

- Preference a short-term outcome over the medium or longer-term impact?

Optimisation in this operating context is not about finding the single perfect version of the plan; rather, its purpose is to discern the next-best version of the plan when new information arrives from outside, or when something breaks in the production chain. And the next-best version of the second-best plan when something else breaks.

An observation from Polymathian’s dynamic decision optimisation projects is that experienced people using heuristic methods make the best (optimal) decisions some of the time, and good decisions much of the time. This is a commendable effort given the complex trade-offs involved. However, they also make far-from-optimal decisions some of the time and these can be costly. Losses add up whether it is missed opportunity in the short term, foregone value in the longer term, or a combination of the two. The goal therefore is to mitigate these losses by using better tools to support better decisions and enabling people to succeed in their job every shift.

Operating confidently in this dynamic context allows the business to adopt an offensive planning stance. The business has confidence in its ability to anticipate and respond intelligently to changes in the operating context. It can take advantage of market upside or of a competitor’s misfortune, achieving this without accidentally impacting the future because the plans are integrated across all time horizons across the whole value chain.

Planning and operating in this space demands the data and decision support tools that result from bringing deep domain expertise together with industrial-strength mathematics: there really is no turning back once you have seen what can be achieved.

Visualise a three-dimensional chart representing your business. One axis is temporal, it spans the time range from decades down to zero-time. The second axis is the value chain, say from orebody to delivered refinery or smelter product. The third axis is the decision maker, from production operator to CEO. Within this framework, consider these focussing questions:

- At each node, what are the critical decisions that the business needs to make?

- In what time horizon windows do these decisions need to be made?

- What information is needed to make the best decision? How do we respond when new information hits us?

- What solution technique is best suited to the type and variety of information, and the type of decision?

- What resources and authorities are required to implement the decision?

- How is the solution checked and tested before implementation?

- How is the effectiveness of the decision measured?

This framework informs the design and delivery of practical decision support tools that meet the needs of an industry seeking new productivity pathways while at the same time faced with increasing external uncertainty. The capability now exists to solve problems across all time horizons and operating dimensions.

The only thing holding us back is our history.

Click here to read the second installment in the 5-part series: Resilience in Mine Planning: Toolkit vs. Mindset

About the author

Rod Smith is the founding Principal of Beresford Advisory, a Brisbane-based resources sector consultancy focussed on supporting better decision making across the mineral value chain. He is a fellow of the Australian Institute of Mining & Metallurgy and a mining leader who was a part of Rio Tinto for over 30 years. During that time he held a variety of technical, operating and leadership roles, most recently as Chief Advisor of Planning & Scheduling. In that role he developed Rio Tinto’s Orebody Productivity framework and established its Operations Research & Decision Science group, building internal and external partnerships in the field of Industrial Mathematics to unlock significant value for the group.

To contact Rod Smith please email: rod@beresfordadvisory.com