The Potential of Digital Twin Technology

“I wish I'd known then, what I know now.” Ever heard or uttered that statement? Ever considered what might have been if you hadn’t ordered more inventory than your warehouse could accommodate? Or if you could have foreseen the impact of a plant shutdown to your supply chain? These are mistakes that could easily have been avoided if given the opportunity of a practice run without consequences.

What then would it mean to your business to be able to simulate future operations or examine what-if scenarios for your processes, products, and networks before committing to change and expending dollars and resources on implementation?

Digital twin technology is enabling businesses to do just that by providing an exact digital replica or simulation of something in the physical world. Digital twins are used to evaluate risk, potential cost, and to better understand and react to changing commercial processes in order to make smarter business decisions.

It is predicted there will be an explosion of digital twin applications impacting all industries over the next few years, and that their proliferation will create more opportunities to find value.

Many industries are already taking advantage of digital twin technology as a training tool for staff, to improve operational outcomes, and even to test new products or procedures before launching them to identify and avoid pitfalls or issues that will be costly to recall and fix.

NASA was one of the earliest adopters of the digital twin concept, using pairing technology to rescue the Apollo 13 mission by solving the problem of how to repair its systems remotely.

As incredible as this achievement was at the time, digital twin applications have since become far more sophisticated.

Asset Twins

At the entry level we have digital twins of physical assets – designed primarily as a reference tool which, for example, enables us to walk around a structure that hasn’t yet been built and view it 10 or even 50 years from now. Asset twins provide a single source for referencing design documentation, supplier details, maintenance requirements and other relevant information.

Asset Twins with Operational History

Add in historical actuals data and your digital twin can now help improve performance throughout the equipment lifecycle. This is typically used in a maintenance scenario, for example to monitor and evaluate wear and tear of a jet engine and assist with design changes over time to improve its lifespan. This more advanced form of asset twin also works with other technology, such as machine learning to understand the relationship between movement and load on asset wear/fatigue and inform predictive maintenance. As a result, repairs are only done when needed and technical teams arrive on-site with the right tools and parts.

Process Twins

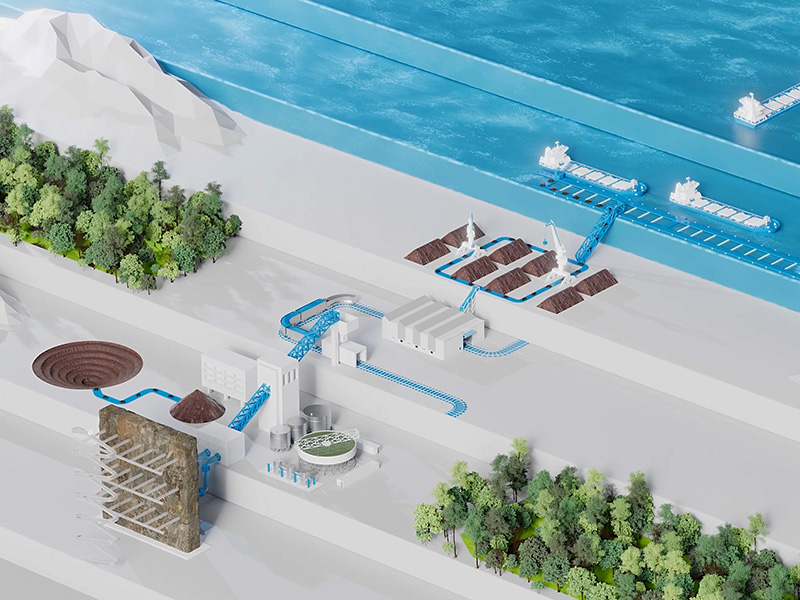

When the process is being mirrored as well as the physical asset, suddenly you can start to see how your assets interact within their environment – to consider both internal and external operational impacts. You now have a visual over entire systems, including their rules and constraints, and the power to analyse the performance of your supply chain. So now when your asset flags an issue, you can look at the entire downstream process and compare future options to select the optimum time for repairs. This is your entry into the world of predictive analytics.

Oz Minerals, an Australian mining company used process twin technology at their Carapateena site in South Australia. The twin made it possible for them to visualise day-to-day operations ahead of time - to observe and test bottlenecks within the caving system, validate operational planning assumptions, and train workers before the mine even opened. (For full project details, see the Case Study in our Related Links below)

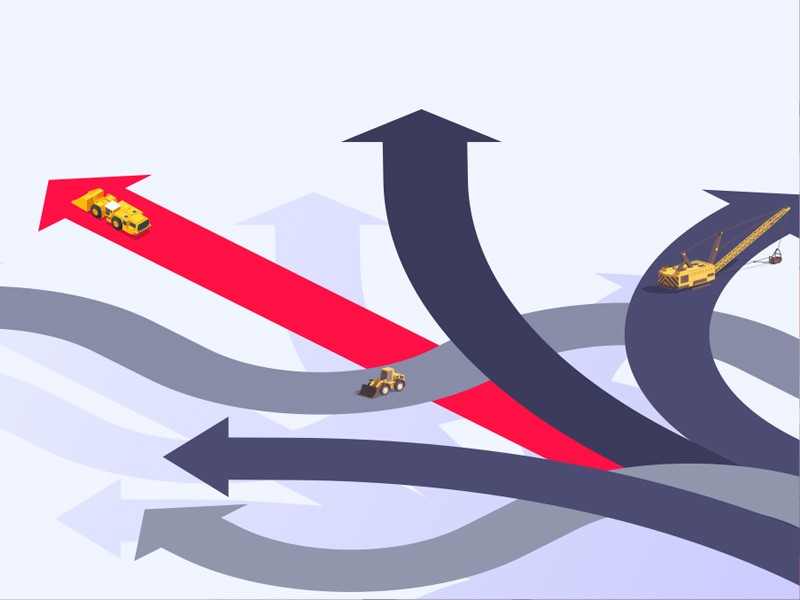

Process Twins with Advanced Analytics

Coupling twin technology with advanced analytics augments a user’s decision capability, allowing them to run hypothetical scenarios and experiment with outcomes. Suddenly they can predict the future and test alternative processes through a virtual replication of the decision-making process – including resource allocation, scheduling and planning decisions that are required for the system to operate.

As a result of this technically-advanced combination, we see digital twins used in hospital emergency rooms to optimise response to emergency situations – examining how many doctors are on call, beds are available, and patients that can be attended to during peak periods. And cities like Singapore, that have a digital twin to help city planners improve their energy consumption efficiency (among other things).

Take it a step further again and use process twins in combination with mathematical optimisation techniques to solve incredibly complex problems in real-time. For several large-scale manufacturing customers in one of the world’s biggest industrial parks, steam and power is being provided by a global energy supplier using this highly sophisticated digital twin technology to manage customer demand and optimise plant efficiencies by 7%. (For full project details, see the Case Study in our Related Links below)

Where digital twin technology becomes a disruptive trend is in its applicability to any operation or problem, its potential impact on industrial processes, and the economic value it can provide. By 2021, Gartner predicts that 50% of large industrial companies will not only use digital twins but see a resulting 10% improvement in effectiveness across the board(1).

Like any application of technology, realising the true potential of digital twin applications requires careful consideration of the business problem you are wanting to solve and how you will assess value from a solution without adding unnecessary complexity.

Related Links:

Case Study: Reducing Uncertainty and Improving Planning Processes with Simulation

Case Study: Improving Operational Efficiency and Profitability for Global Utilities Supplier

(1) SMARTER WITH GARTNER, SEPT 2017. “PREPARE FOR THE IMPACT OF DIGITAL TWINS”