Mining

Mine to market optimisation software to maximise value chain efficiencies across all time horizons

Multi-mine

Develop plans that handle multiple mines with shared resources

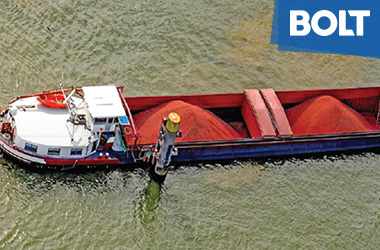

Pit to port

Develop plans that consider and react to the entire supply chain from pit to port

Resource agnostic

BOLT is able to handle any mined resource with any attributes

Holistic Planning

Mathematically optimise across all aspects of the mining value chain to efficiently plan the movement of material from supply to demand whilst maximising margins.

Mining Digital Twin

Model complex multi-mine value chains to codify operating rules, costs and constraints to explore the impacts of various scenarios on the system.