Transforming Mine Scheduling with Industrial Mathematics

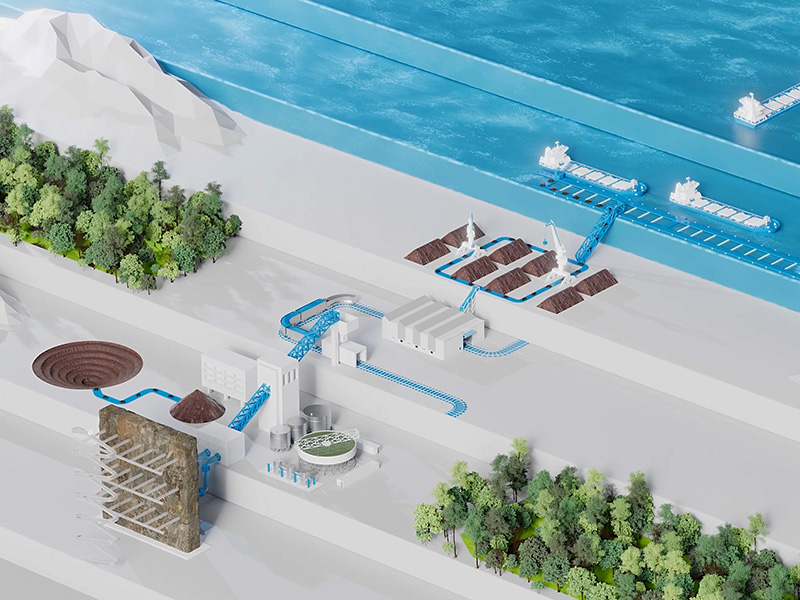

Mines are highly asset intensive operations that must deal with complex planning problems at scale. The constant demand to extract valuable resources at the least cost, while maximising profitability and net present value (NPV), are driving mine managers to explore better ways of fine tuning and optimising their processes.

Mine planning is one area where improvements in the scheduling of mine activities can significantly increase NPV and improve asset performance – from the utilisation of equipment, drilling, blasting and material handling tasks, to prioritising mining areas and resource allocation.

Formerly called ORB, enhancements to Polymathian’s optimisation tool, APEX, is empowering mine planners to consistently produce higher quality underground strategic mine plans that increase a mine’s NPV.

APEX harnesses the power of cloud computing and Industrial Mathematics to solve complex strategic problems quickly, all of which aim to optimise mine schedules.

Polymathian’s APEX Technical Director, Dr. Ben Hollis says, “APEX is a unique mathematical optimisation tool that can deliver the competitive edge our mining clients have come to expect. It utilises mixed-integer linear programming to generate solutions, which is a fundamentally different technique to other tools on the market. Based on the recent enhancements made, mine planners can now solve larger, more complex problems quicker.”

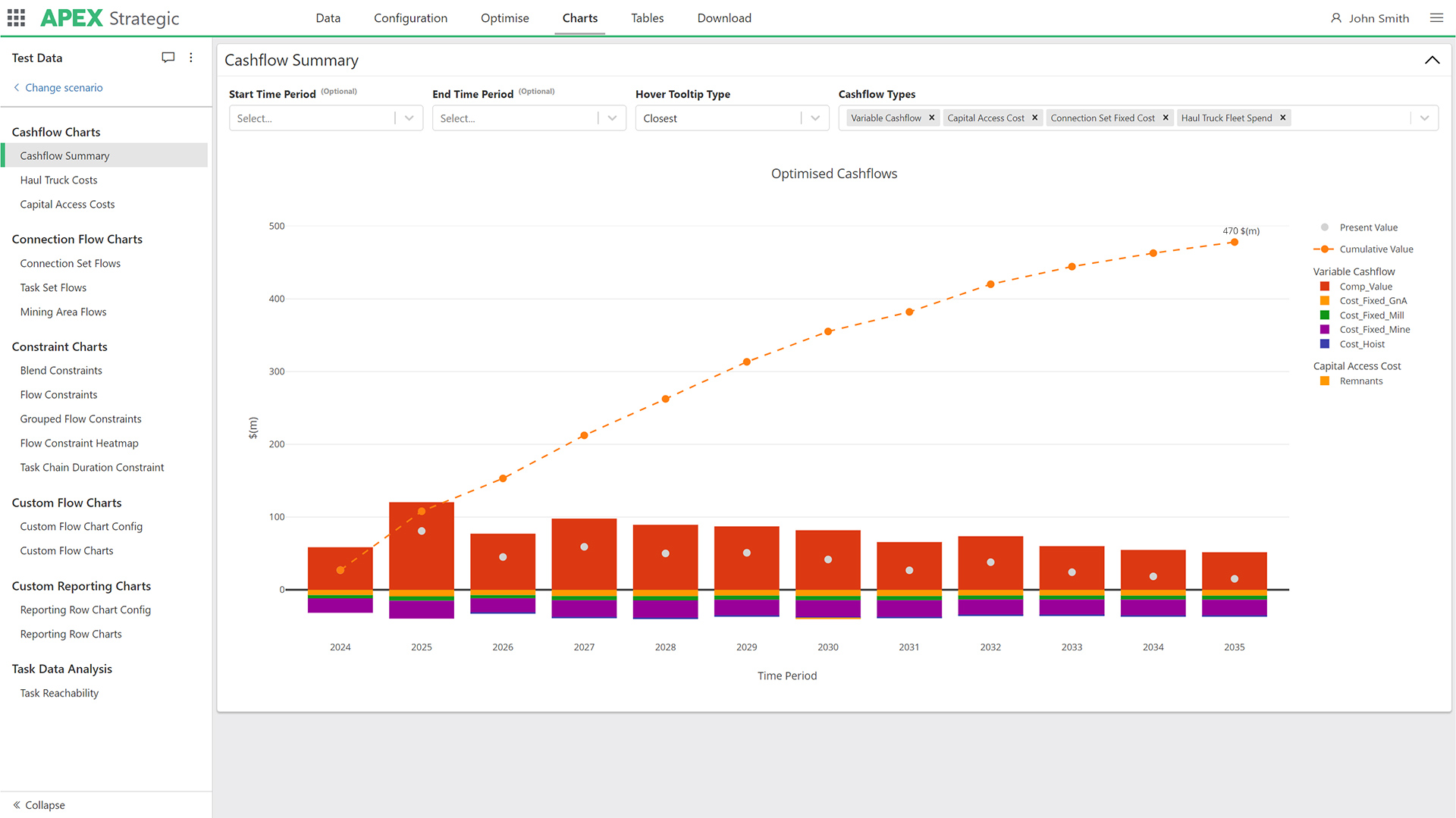

APEX screenshot showcasing the cashflow summary

Benchmarking Performance

Polymathian continually invests in product upgrades and benchmarking to ensure their solutions meet the highest industry standards and client performance requirements. Following several software and algorithm enhancements to the APEX tool, Polymathian recently conducted a benchmarking assessment against other optimisation tools on the market.

Results found that APEX consistently produced higher quality schedules in a shorter amount of time. Not only did it increase a mine’s NPV by an average of 10 percent (potentially up to hundreds of millions of dollars in value for clients), but it achieved solve times 20 times faster compared to other tools.

APEX is a 'run-once' solver, eliminating the need for manual guidance or the need to provide mining priorities to produce a solution. In contrast, other tools may employ adaptive search algorithms, meaning users need to manually perform multiple runs, feeding the output of one run into the next, in an attempt to generate better solutions. This can be exceedingly time-consuming.

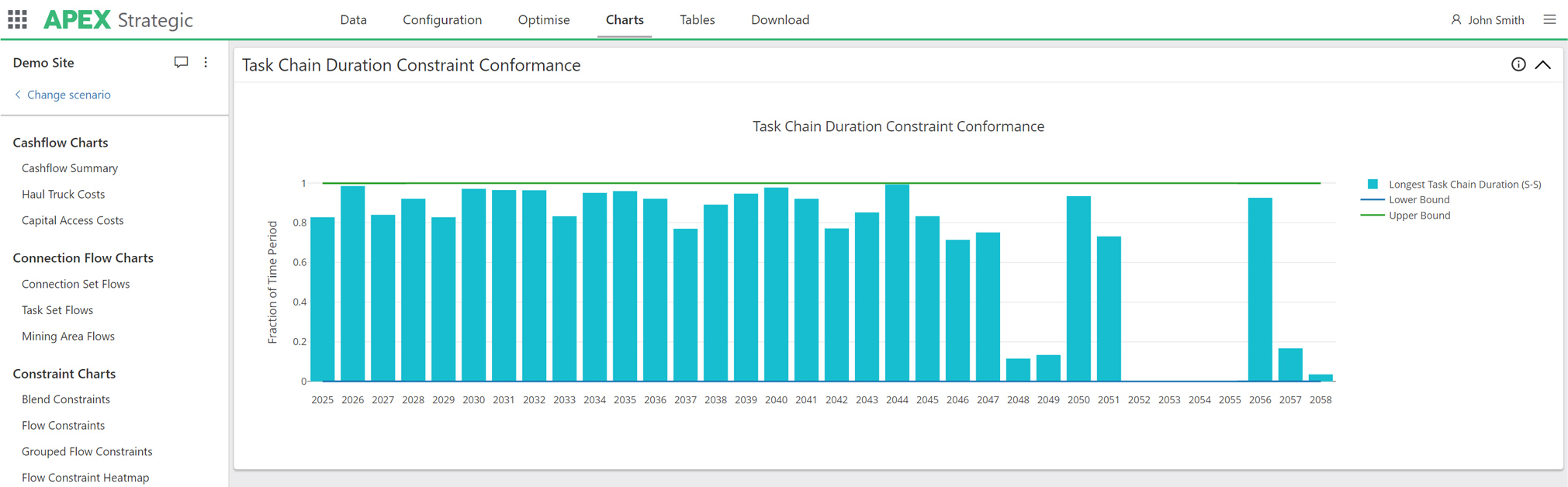

“During the benchmarking, we’ve placed a lot of emphasis on ensuring how we model the most complex aspects of underground mine planning, such as the mining rate,” said Hollis.

“Enforcing the mining rate constraint during the optimisation process, in the smartest way possible, is one of the more challenging aspects of modelling the underground mine scheduling problem. Consider two tasks, where one is down the dependency chain from the other. The duration to complete all the tasks (and potentially the dependency arcs between these tasks) in the dependency chain between these two tasks defines a minimum separation between these two tasks in any feasible solution. For example, if there are two tasks, with 156 tasks between them each of which takes a week to complete (with no dependency lags) then these two tasks must be separated by at least 3 years wherever they appear in the schedule. Enforcing this fundamental constraint for all task pairs, down all dependency chains, in the most efficient way possible is key to engineering a high quality optimisation tool.”

APEX conforming to not exceeding the allowable tasks in a given time period

An Optimised Overhaul

APEX is purpose-built to optimise mine plans that feature a wide range of input parameters – whether it’s development and production tasks, geological constraints, equipment availability and fleet performance, ore grade and attributes, or CAPEX, OPEX, contracts and revenue targets.

The tool can readily integrate with a mine’s design package to produce optimal schedules at the push of a button. The mathematical engine has been designed with mining at its core, which is reflected through its recent enhancements.

By overhauling how APEX’s engine formulates problems and produces answers, the speed at which problems can be solved has doubled.

“Our algorithm has become even smarter when managing complex dependencies,” said Hollis. “This has reduced the dependency network to the minimum required to solve problems, which means it’s easier to consume more detailed SCHED files with different task dependencies between them.”

The overhauled variable cut-off grade optimisation feature provides users with the ability to define multiple stope options for APEX to select during run time. This means that it can make trade-off decisions with varying stope sizes that may represent different cut-off-grades to maximise the value of the mine.

“On the technology platform side, the task-on-demand (TOD) feature used by APEX, orchestrates cloud computing resources on demand for each scenario." said Hollis. "This means we can make available on demand, appropriately sized, extremely fast compute resources, so that users can solve truly enormous problems as fast as possible, and run multiple scenarios in parallel”

Aside from APEX’s core features, additional improvements to charting and reporting now provide users with more ways to analyse scenario results. The implementation of a new scenario manager allows users to more readily manage scenarios or datasets at scale anywhere around the world.

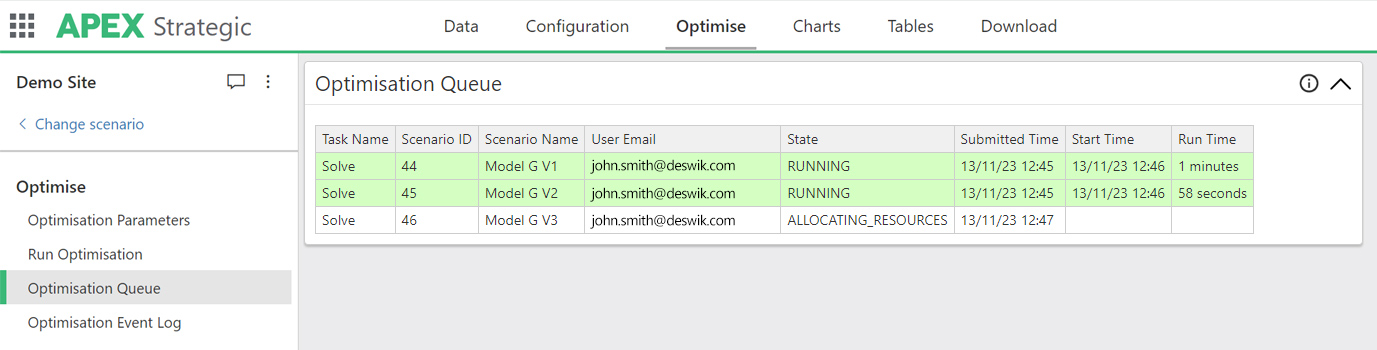

APEX's optimisation queue provides insights into pending solves

Collaborating for Success

Since integrating with Deswik, Polymathian's expertise in automated decision-making and Industrial Mathematics, along with Deswik's advanced software tools for mining, has significantly enhanced our ability to deliver transformative value to our clients.

“Joining Deswik has given us unique access to a team of mining subject matter experts to help accelerate enhancements across our product suite, while also streamlining the implementation process,” said Hollis.

“However, our solutions wouldn’t be possible without the support of our clients. We take pride in building collaborative partnerships that not only help them overcome their specific mine planning challenges, but provide us with the insights we need to develop faster, more responsive tools.”