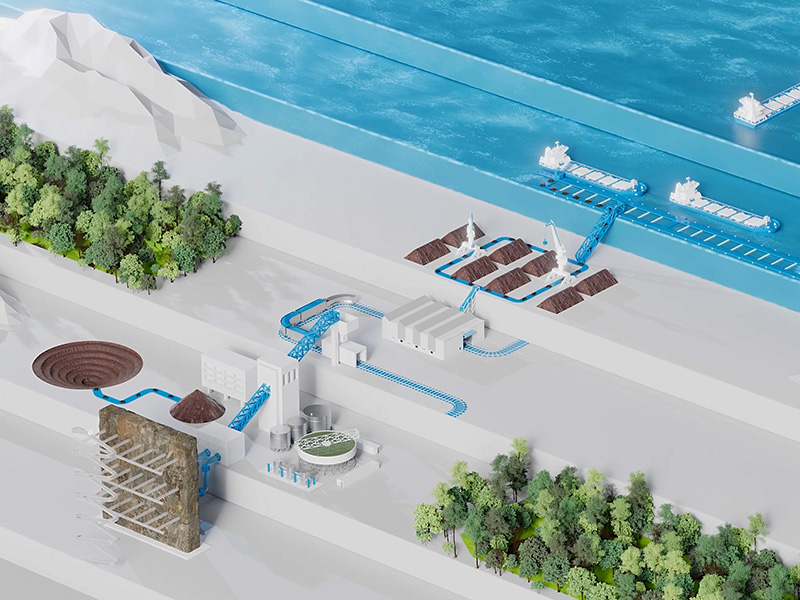

Streamlining mine to market value chains

The modern mining value chain is a complex environment with many intertwined sub-processes, all of which need to be synchronised into an efficient operation. Coordinating this entire process—from mineral extraction, crushing, refining, and processing to stockpiling, blending, and shipping—while overcoming various system constraints, poses significant challenges.

For over a decade, Polymathian’s multi-commodity blending and logistics optimisation software, BOLT, has helped mining operations mathematically optimise planning and decision making across all stages of the value chain.

Recent enhancements to the product centred around improving workflow, control and usability, are set to further streamline the critical mine-to-market planning process, while maximising margins.

Streamlining data integration, scenario creation and comparison

API that’s intuitive and powerful

Mining companies and their digital systems are increasingly relying on integrations to provide data for decision support tools such as BOLT. BOLT has improved data integration options via a more user-friendly application programming interface (API).

The upgraded API enables users to push data from their data warehouse to BOLT, and have BOLT send back published plans. For example, transferring opening stock levels, plant maintenance profiles, and vessel status is as simple as clicking a button. BOLT also facilitates seamless integration with other systems and data sources, allowing users to leverage their existing IT infrastructure productively.

Scenario creation and comparison to understand complexity

Tao Vink, BOLT's product manager, explains that “BOLT’s new API makes it easy for users to create many scenarios and run what-if analysis. By generating alternative options for mine plans or maintenance profiles, users can explore different ‘what-if scenarios’ and assess the potential outcomes, to anticipate and mitigate risks more effectively. This level of holistic flexibility empowers users to experiment with different strategies, facilitating innovation and continuous improvement within supply chain operations.”

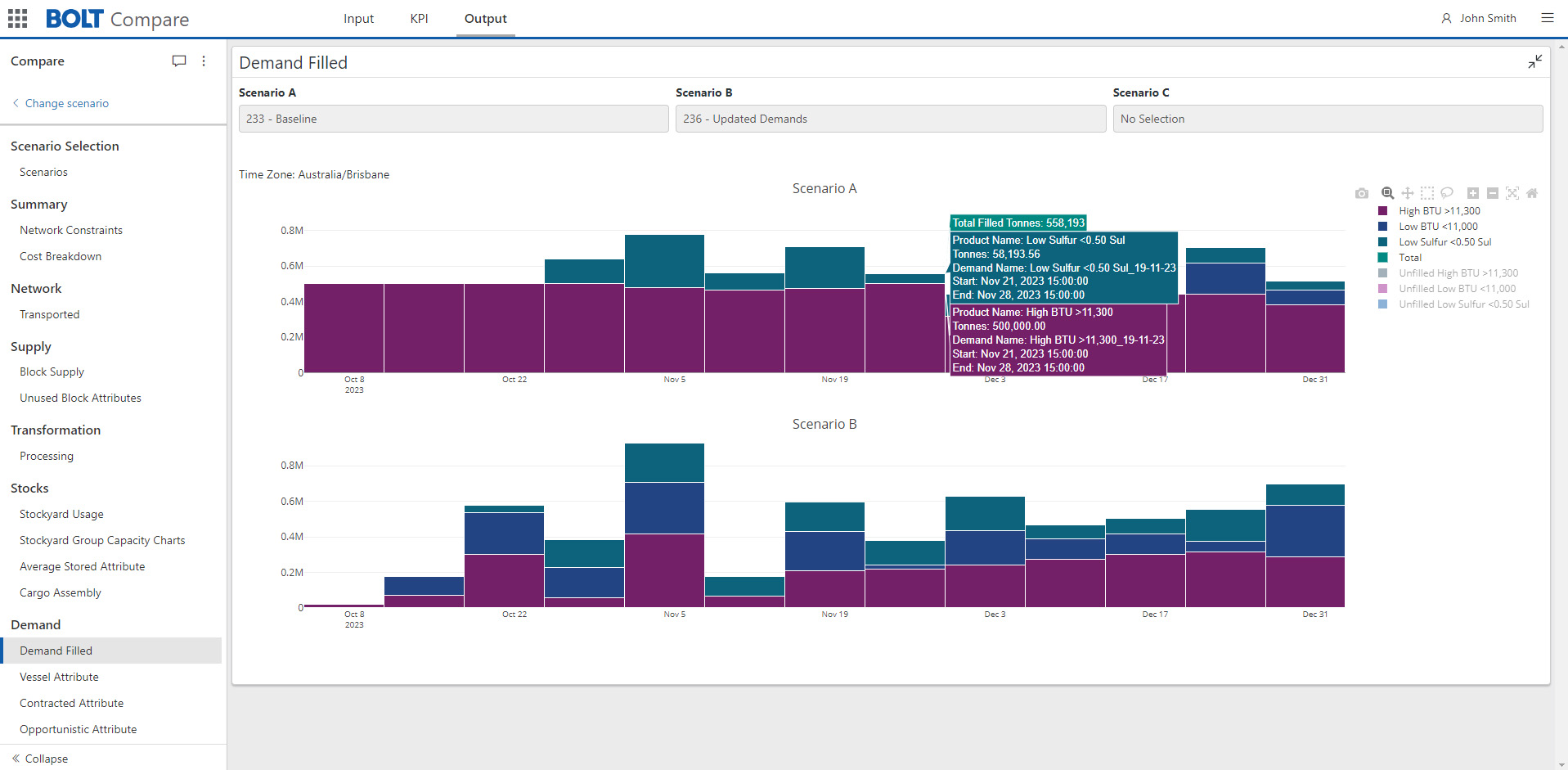

Scenario comparisons, an exciting new feature, allows users to evaluate the impact of different decisions on KPIs, helping identify the most appropriate course of action. “We are seeing more time spent by planners analysing and comparing possible scenarios, learning from them and providing more in-depth insight back to the company” added Vink.

The time taken to create and run scenarios have improved with a substantial reduction in pre-solve network generation time, meaning users can optimise and plan much larger models with ease.

The combination of improved data integration, scenario creation and comparison has streamlined the role of planners significantly.

BOLT screenshot showcasing the scenario comparison

Modelling enhancements deliver more control to planners

Vessel sequencing and co-shipping

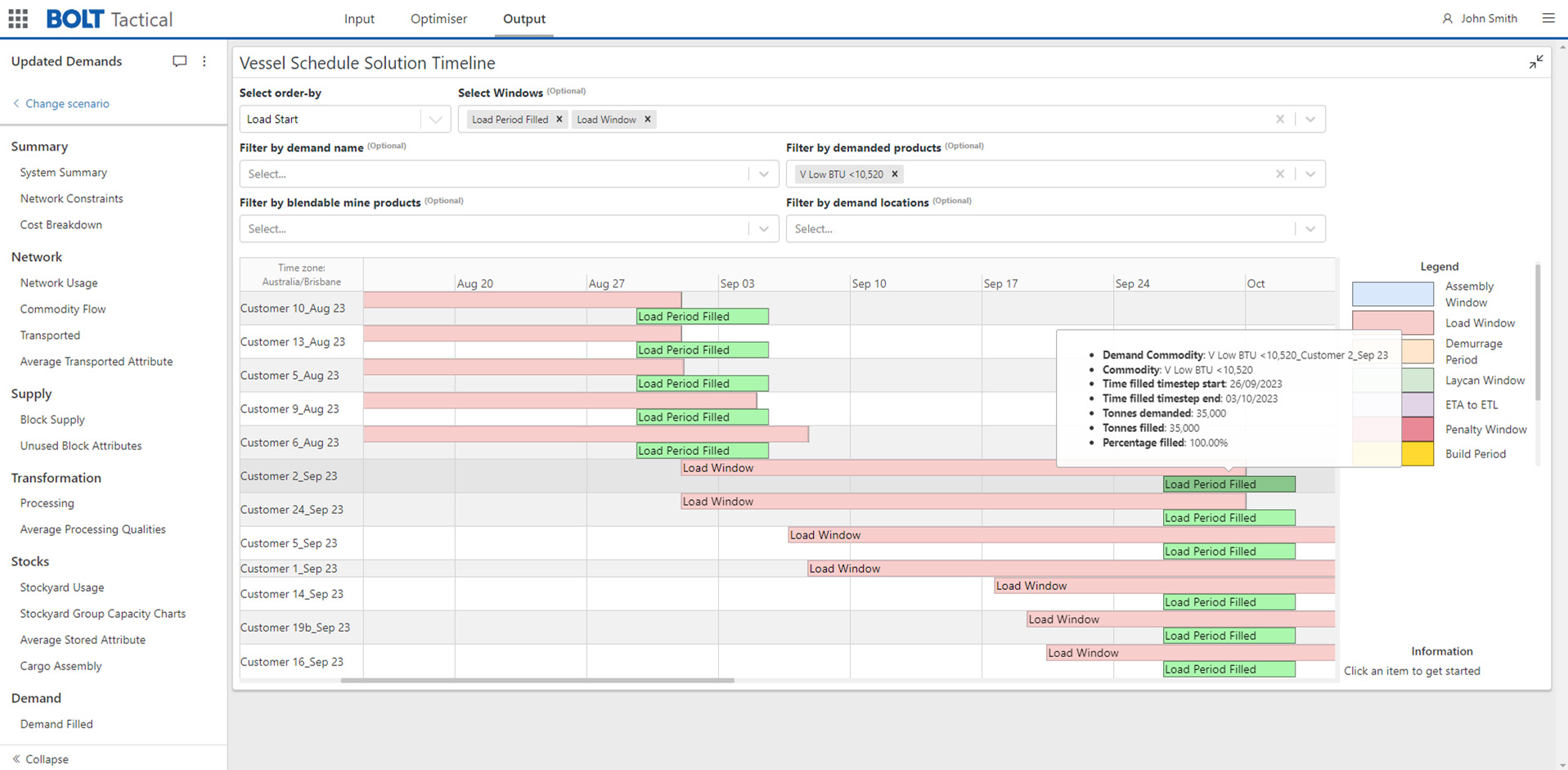

Vessel planning enhancements saw the BOLT team prioritise modelling improvements in relation to vessel sequencing and LAYCANS.

Vink highlights that users can now specify the order in which vessels are loaded at a port. “For instance, users can dictate that vessel 1 must be loaded before vessel 2, while vessel 3 can be loaded at any point.” This gives users more control when they need it, while allowing BOLT to minimise demurrage costs (incurred when vessels are delayed at port, waiting to be loaded). “Demurrage costs are significantly reduced when BOLT can align vessel schedules with the availability of supply materials, potentially saving millions per year” added Vink.

The latest enhancements to BOLT included support for co-shipping where vessels carry multiple products. This greatly improves BOLT's modelling capabilities, which allows users to accurately represent real-world shipping scenarios, specify minimum tonnage requirements for vessels, optimise loading, and reduce demurrage costs whenever possible.

BOLT screenshot of the vessel scheduling timeline

Live module material tracking

BOLT’s Live module estimates stock levels and grade quality by tracking material movements on and off stockpiles in near real-time. “This tracking is indispensable for operational planning, providing details on stockpile content, in-transit trains, and vessel statuses.” highlighted Vink. Significant improvements to the material tracking algorithms have been made to give planners more control.

Data editing and review

BOLT grids now feature rule-based cell colouring, which adds an information layer for users. This can be used to highlight errors in cell rows or values, prompting review. There is also a new ‘undo/redo’ option for grid edits, and improvements to the demand timeline chart, which allow direct data editing from visualisations to further streamline the user experience.

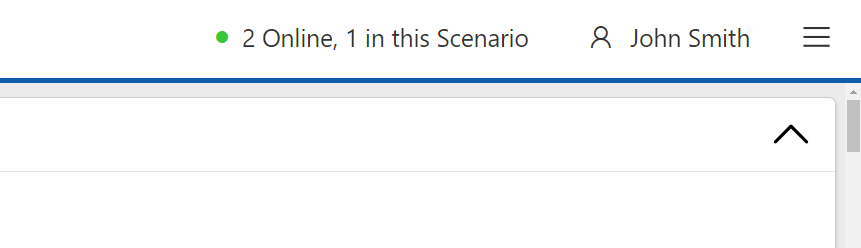

A new “Presence” system has improved team collaboration by allowing users to see the current scenarios other team members have open.

BOLT's Presence System

Upgrades designed with the future in mind

Additional features and enhancements are already in development to ensure BOLT remains the supply chain optimisation tool of choice, now and in the future.

The heavily requested tonnes-weighted averaging stockpiling feature that will offer alternative aggregation methods for stockpiles beyond FIFO and LIFO is also well into development.

Vink says, “the addition of flow fields will introduce a new constraint type giving users the ability to enforce constraints on both tonnages and material composition. This will facilitate more nuanced and effective supply chain rule adherence.”

With the increasing integration capabilities offered, further automation will become the next core focus. “The ability for the BOLT system to automatically pull the latest data, optimise and then have plans ready for planners to review when they start in the morning, is where we see BOLT developing next,” he said.

BOLT’s upgrades reflect Deswik’s commitment to continuous product advancements in response to the evolving needs of its users across the entire mine value chain. The role of BOLT will continue to be an industry leader in aligning mine production and demand in a way that consistently adds value to the pit-to-port supply chain.