Polymathian’s simulation capabilities will be on display at this year’s Winter Simulation Conference

Polymathian’s simulation team had three abstracts accepted for presenting at the annual Winter Simulation Conference. The both in-person and virtual conference will be held in Phoenix, Arizona, from 13-17 December 2021. All three of Polymathian’s presentations will be held virtually on 17 December.

Application of Simulation Optimisation to Minimise Downtime

ABSTRACT

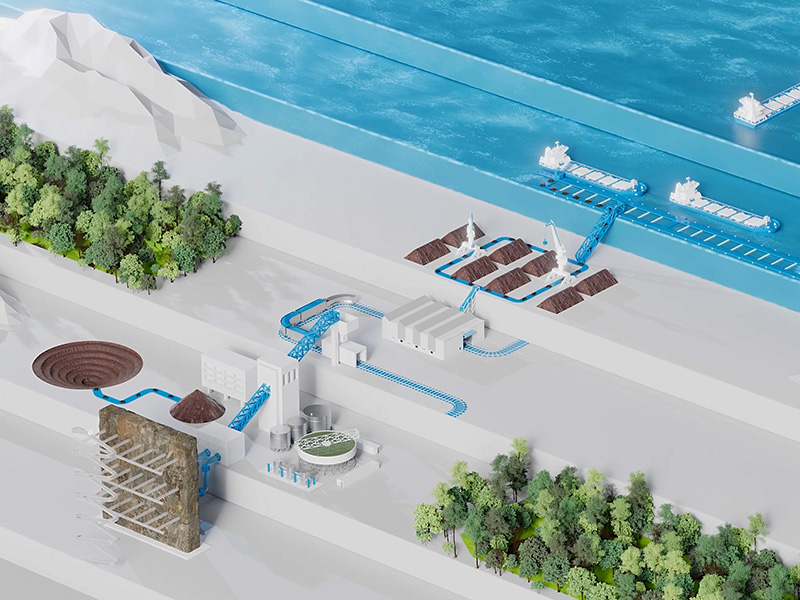

In this case study, simulation optimisation is used to minimise the inventory required to meet a target level of unplanned outage time (or conversely, minimise the cost of downtime for a given inventory level). A large inventory of conveyor belts is maintained as insurance stock to minimise the cost of downtime associated with conveyor belt failures. Hundreds of conveyors are used across multiple sites, each with a different probability and cost of failure. A MIP formulation is used to optimise inventory holdings for each belt material type. Conveyor belt failures are then simulated over a long period of operations to provide an assessment of the likely range of performance for the optimised conveyor belt inventory and comparison with the existing inventory. The study provides a relatively simple application of simulation optimisation that has the potential to deliver significant value to operations with large spare parts inventory holdings.

Virtual Presentation: Friday 17 December 1:00-1:30 pm MST | Manufacturing Optimisation Track

Haulage Simulation with Complex Allocation and Tactical Stockpiling

ABSTRACT

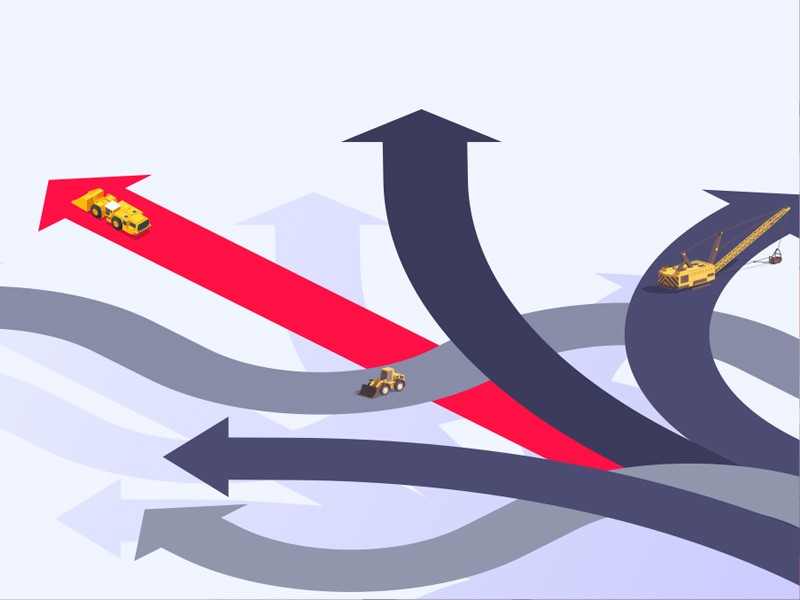

Haulage is typically the largest single cost in open pit mining operations. Small improvements in haulage operations for large open pit mines can translate to significant returns. Delays due to queuing at shovel locations, crushers and dump locations can add up to a significant proportion of the average truck cycle, presenting an opportunity for savings if the causes for queuing can be identified and addressed. Simulation of haulage operations is an essential tool for both understanding the causes for operational delays and testing potential solutions. Simulation of haulage operations requires representation of fundamental truck cycle activities, ancillary activities and movement interactions on complex networks. It also requires simulation of complex decision making if there are many alternative source locations and destinations for different ore types and waste. This presents a challenge for developing a good simulation model representation, but also provides an environment where simulation analysis can deliver significant value.

Virtual Presentation: Friday 17 December 2:30-3:00 pm MST | Haulage Operations Track

Simulation of Carrapateena Underground Haulage Operations

ABSTRACTTruck haulage for underground mining typically operates on single width roadways, often with limited opportunities to pass returning empty and loaded trucks. Vehicle interactions and associated waiting delays at passing bays and turnouts can accumulate to be a substantial proportion of overall average truck cycle times. This limits the total capacity of the haulage system. Incidence of vehicle interactions can also change significantly with haulage throughput, truck fleet size and changes in haulage routes over time. This case study describes the application of simulation of the haulage operations at the Carrapateena underground mine in South Australia to evaluate the future capability of the haulage system. The representation of haulage operations includes detailed truck maneuvers to manage campaigning and passing of multiple trucks and management of ore and development waste stockpiles to both feed the downstream materials handling system and allow the upstream mine production and development to continue operating.

Virtual Presentation: Friday 17 December 3:00-3:30 pm MST | Haulage Operations Track