Modelling your next big business improvement with simulation

Is your team about to pitch a big process improvement? Have you considered all the variables that this change could potentially impact? Leveraging the power of simulation allows businesses to analyse proposed changes in a virtual environment without risk. Simply put, simulation helps teams make better business decisions.

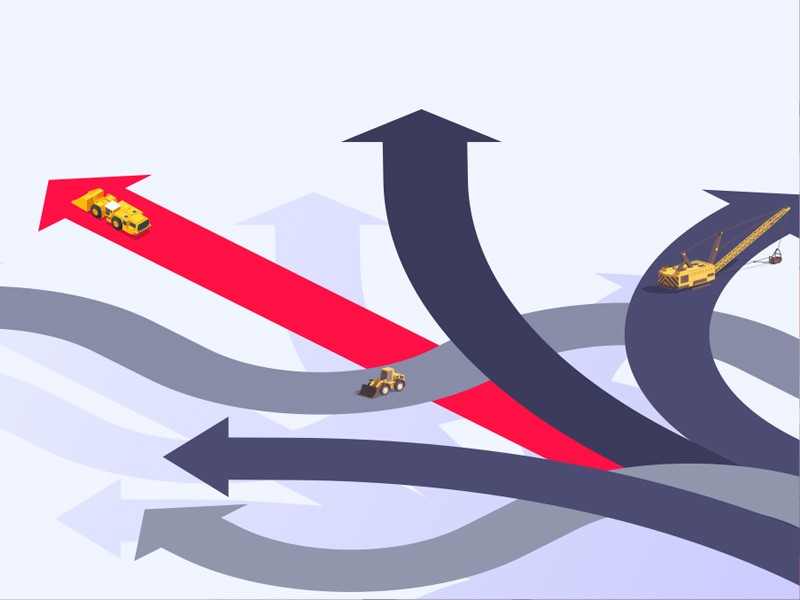

Removing the risk of implementing business improvements enables businesses to leapfrog into the future by transforming how they operate today. The ability to test alterations to your system in a digital environment allows businesses to move the next business improvement idea from concept to implementation confidently. And not just one idea, but the ability to test an array of process changes to discover their impact on operational performance.

"Removing the risk of implementing business improvements enables businesses to leapfrog into the future by transforming how they operate today".

The avalanche of operational data that is now available thanks to the internet of things has made simulation even more effective at modelling complex business processes. The mass availability of transactional operations data from equipment movement to inventory levels to employee shift changes, has dramatically refined the accuracy of how a simulated system will respond to various inputs.

Discrete Event Simulation to Evaluate the Performance of Complex Systems

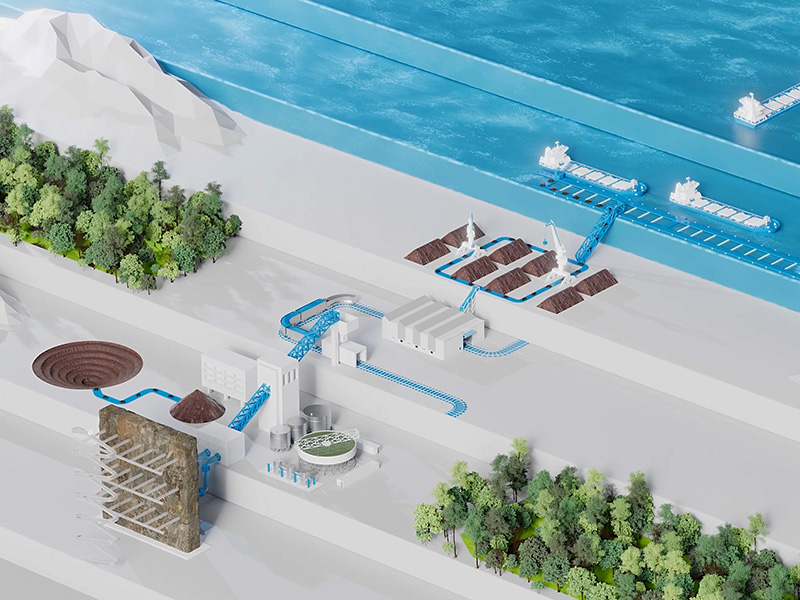

Within heavy industry, discrete event simulation is often used to evaluate CAPEX investments prior to commencing due to its ability to predict under what conditions a system will fail or what capacity it can sustain. Discrete event simulation involves complex interrelated workflows of materials, parts, or people through a business process or system that progress over time. This form of simulation is beneficial for modelling systems that include attributes such as queuing and decision logic. Creating a simulation model of how a system operates enables bottlenecks to be identified and evaluate performance improvements with the bottlenecks removed.

- Assess the performance of an existing system under different conditions or with different strategies (higher throughput, different decision logic, etc.)

- Evaluate the performance of a modified version of the existing system (e.g., upgraded rates, more storage, more machines)

- Analyse the performance of a future system design

The value of simulation is its ability to evaluate system performance with complex interactions to discover the likely range of system outputs. The quantitative understanding informs strategic and operational decision-making and minimises capital and operating costs. Furthermore, understanding the effect of a system's configuration on operations performance allows the best decisions to be identified, especially where options are finite and potential outcomes are difficult to determine otherwise.

Simulation is an essential tool for operations with the following characteristics:

- Tasks are shared between resources, such as stacker-reclaimers in a bulk export terminal or shunt engines in a rail yard

- Where there are interactions between entities within a system or across interfaces, such as queuing in a truck haulage operation or delays in a stockyard causing trains to miss the next train path

- Where constraints related to a sequence of events exist, such as ships berthing on a continuous quay-line where the mandatory distance between ships affects what ship can berth next

However, complex modelling isn't always necessary. Business processes that are relatively straightforward and do not exhibit the above characteristics can be solved using a static model—for example, calculating the carrying capacity of a single haul truck. But if the same hauling operation involves multiple trucks with interactions between them, this would require simulation to provide an accurate evaluation of carrying capacity. The model could then be used to determine the impact on production if you increased your haulage fleet and subsequently assess those gains, if any, to warrant the CAPEX investment required.

When used for strategic decisions, simulation is particularly compelling when combined with mathematical optimisation tools. In addition to aligning real-time decisions with strategic goals, simulation provides real-time performance visibility now and for the life of the operation. The simulation results can be fed into a mathematical optimiser that prescribes the best scenario (solution) to deploy to satisfy commercial objectives.