Modelling a supply chain to evaluate potential cost savings highlighted a different wash strategy as key

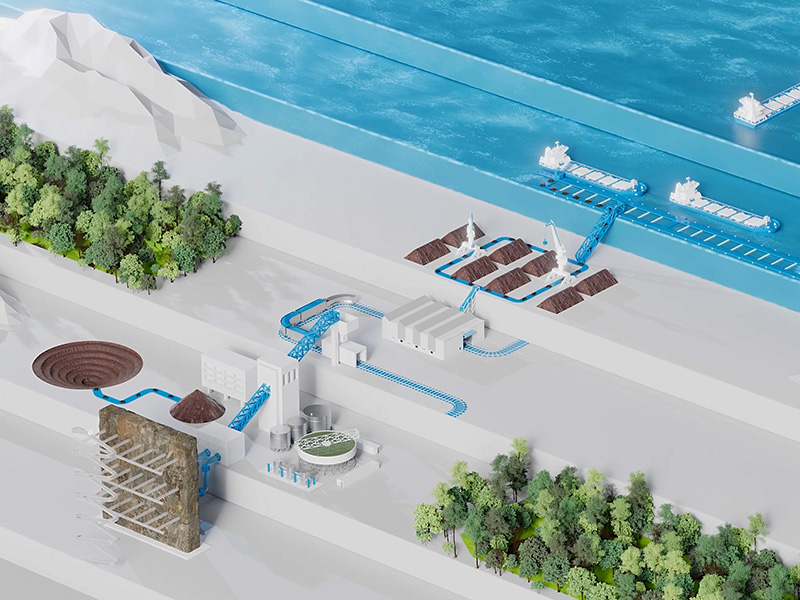

Our client is a vertically integrated energy company with coal, gas and water assets used to generate electricity. Polymathian modelled one of their supply chains comprised of coal mining operations, stockpiling, processing, bypassing and conveyors to several coal-fired power stations.

The objective of the study was to reduce costs by maximising the energy recovered from mined resources and identify the most cost efficient way to move coal through the supply chain.

With limited decisions available for optimisation within the network due to the demand constrained environment, they sought a way to evaluate the potential for cost savings by operating differently, and yield more energy by setting a different coal wash strategy enabled by blending.

Determining the best operating strategy, one with lowest overall system cost and highest power plant efficiency is complicated to calculate. Here’s a breakdown of why:

There are 5 options for processing coal, each targeting a specific ash: 24%, 26%, 28%, 30%, and 32%. Washing to lower specific ash has the following advantages and disadvantages:

Advantages:

- costs less when processed at the power plant (reduced ash handling)

- has a higher energy density and therefore are cheaper to move through the network on a per GJ basis (more energy moved in less tonnes)

Disadvantages:

- costs more to wash

- lower yield results in less material

- typically recovers less energy overall

When power stations feed high ash coals, they are limited by the ash handling pump which has a maximum throughput rate. This rate determines the maximum generating capacity when feeding coal of a particular ash value. As such, defining where potential value exists and is viable is critical to driving cost saving opportunities and decisions.

BOLT was able to take into account the complicated trade off’s between cost and energy efficiency. The outcome of the study is a robust strategy that considers the entire supply chain.

Results point to potential cost savings of between 2% and 6% due to a strategy that:

- better sequences the mine plan to align with demand

- decreases stock holdings

- direct feeds from processing plant to power stations more often

- washes majority to 24% ash

- correctly selected material to bypass or wash to other specific ash targets, mostly 26% and 28%

For more information, or to book a demo, visit bolt@polymathian.com