What is Short Interval Control?

Short Interval Control (SIC) is a production management process whereby workers provide progress feedback against an expectation around their allocated tasks per shift and advise managers of issues or deviations in real-time.

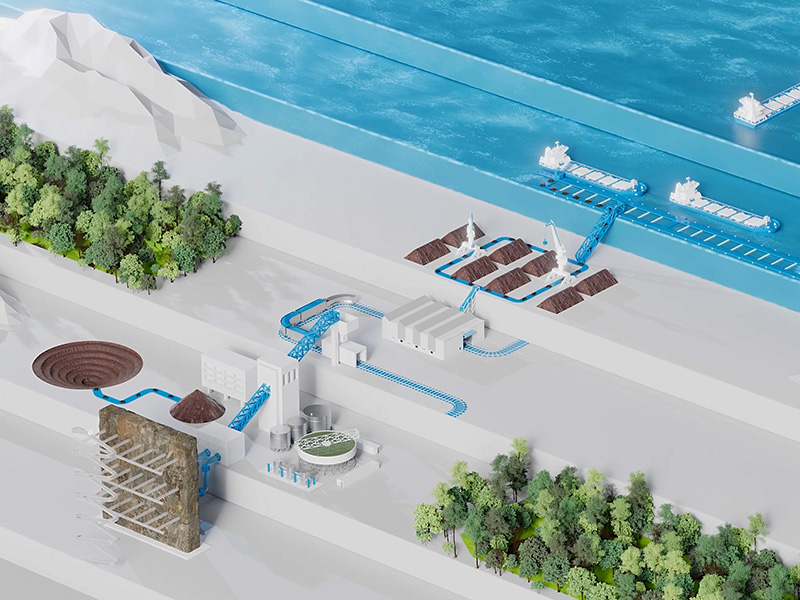

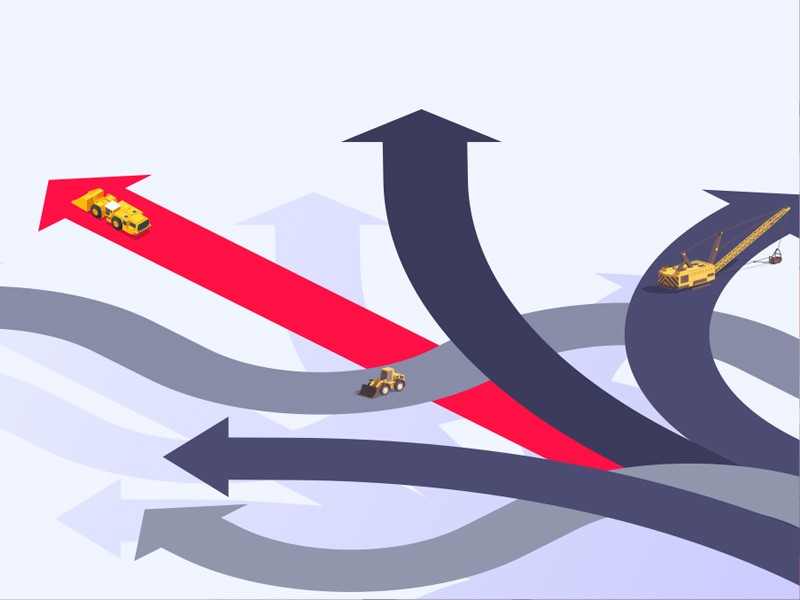

This process enables shift managers or the control room to intervene or adjust decisions to cater for any changes and minimise deviation from production targets. In its most advanced form, it enables continuous, autonomous dispatch of optimised instructions to various operational systems that support a strategic plan.

Traditionally used in manufacturing, technological advances in data capture and communication infrastructure have created new opportunities for shift management processes in other heavy industry sectors.

In fact, any business which revolves around activities where variation can cause issues can benefit from Short Interval Control. By being better equipped to make decisions backed by data and equipping and empowering employees to measure their own performance against a planned goal, SIC can produce rapid improvements to productivity.

Potential benefits to business

- Real-time situational awareness to effectively monitor tasks and progress

- Real-time visibility over resource availability and variations

- Knowledge of operational priorities to support decision making in the event of unexpected issues

- More effectively measure improvements in productivity and efficiency

- Improve production output and thus lower costs

- Monitor compliance to long-term objectives and track variations to establish a business case for change where required

- Develop trustworthy strategic and tactical plans to develop realistic goals

Look at the manufacturing industry where SIC originated - it is largely based on complex operations involving management of multiple tasks, often occurring simultaneously and dependent on output consistency. Yet this is true of many complex operational business models, from mining to logistics or aeronautical industries where SIC is able to provide immense value.

Ensuring you have the right measurement system built on relevant intervals within your processes is just one part of successful SIC. Assessing trends via frequent performance measurement against business objectives needs to be backed by an analysis of causes and avoidance of issues. Where SIC becomes powerful is in real-time dispatch of decisions in support of key longer-term goals, that are continuously optimised and reconfigured based on feedback.

As the appetite for increased control and automation in industry grows, and with many industry leaders already seeing significant productivity and cost improvements from short interval control practices, the fact remains that there are few readymade solutions available and the transformation requires careful integration within each organisation’s operational constraints and production objectives.

There seems to be little doubt Short Interval Control practices as part of a sophisticated overall management operating system can contribute to increased production and reduced operating costs. The trick lies in ensuring you are making the best decisions based on the best overall strategies for your business.