RACE Animation for Improved Data Visualisation

Polymathian's RACE, a rail supply chain optimisation software that uses industrial mathematics to maximise throughput and asset utilisation, has released a new animation feature to help bring your planning and scheduling solutions to life.

RACE users are now able to add dynamic visualisation capabilities to their planning toolbox, making it easier to understand each optimised solution.

For bulk systems with many cooperating stakeholders who need to share rail infrastructure, planning journeys to deliver cargo on time and at minimal cost is challenging. The RACE optimisation engine solves complex rail-based planning and scheduling problems to efficiently move material over rail systems noting maintenance, network outages, and other events impacting network throughput whilst meeting contractual obligations. Understanding how planning decisions may affect throughput in these complex networks is essential to maximising the system's profitability.

For instance, timing is critical when planning multiple disparate track maintenance events to minimise disruptions to all participants. Understanding the impacts to network throughput and contract serviceability whilst meeting the maintenance objectives is incredibly complex and time-consuming, especially when done manually.

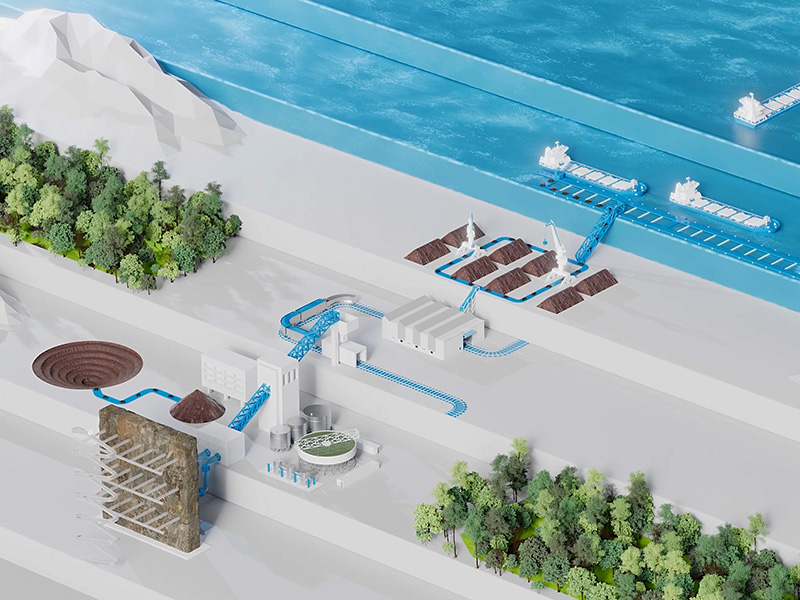

Let's look at an example of a large bulk haulage network with multiple producers utilising shared rail and port assets. In the figure below, RACE produced an optimised rail schedule for two haulage providers needing to fulfil contracts for six bulk producers railing across six terminals, both domestic and seaborne export.

Visualise your optimised rail plan

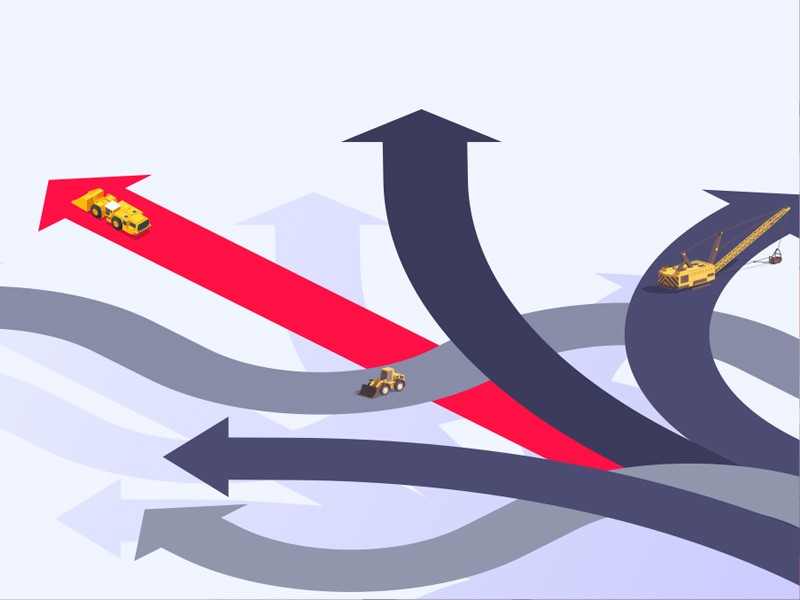

- What if planned maintenance on a particular branch line creates an unavoidable chokepoint within the network?

- What impact will this maintenance event have on the production profile of each producer?

- How does the network serve contractual demand and still meet its overall maintenance requirements?

RACE allows network operators to manage complex maintenance requirements by applying sophisticated industrial mathematics techniques to produce optimal rail schedules. With a click of a button, RACE enables planning teams to rapidly run a range of test scenarios to gain insights into when the optimal time would be to schedule track maintenance. What would have taken days to plan manually can now be done optimally within minutes. In the figure below, planners can now visualise each scenario and how the network would respond to the maintenance events.

Visualise RACE replanning around maintenance events

RACE optimises the entire network simultaneously to ensure that every available minute of the day is utilised to capacity, especially in constrained environments. Having total visibility over the whole network. With additional business insights and dramatically reduced planning times, RACE users maximise asset utilisation, resulting in the maximum amount of tonnes moved through the supply chain.

For more information, book a demo today