Polymathian experts provide insights into the future of simulation

For decades simulation has been used with great success to debottleneck manufacturing operations and model complex operations for planning purposes. But what does the future hold for Simulation? According to Polymathian's Head of Simulation Colin Eustace, the recent increase in data availability and system connectivity has significantly expanded the application of the technology. As with just about everything, the landslide of digital data has been a game-changer.

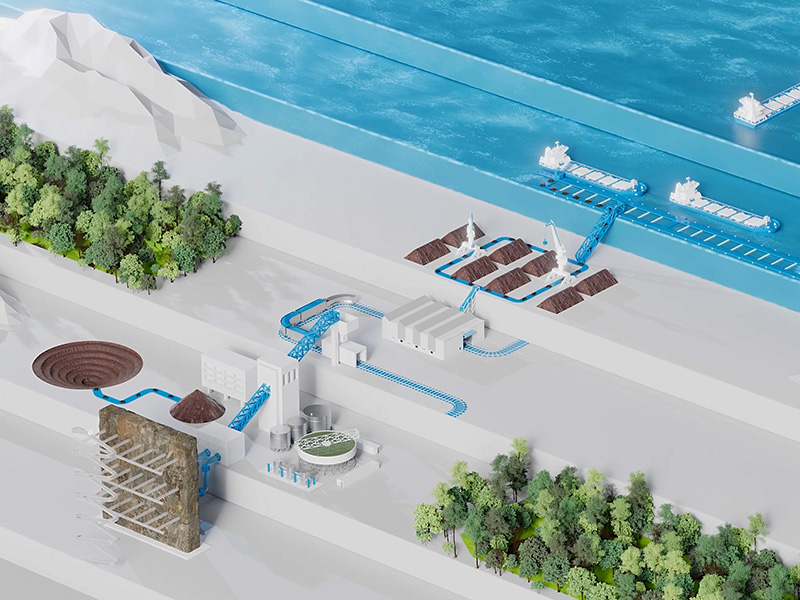

Simulation is an essential tool for answering business problems that require the performance evaluation of a complex operational system. Operational complexity arises from interactions between system entities, task sharing between equipment or constraints related to an event sequence. The performance of these complex systems cannot be calculated using a static model, which is why simulation is used to identify system bottlenecks or the best upgrade options.

"Simulation is all about understanding complexity and is ideally suited for illuminating the risks associated with our client's businesses," said Michael Dallimore, Polymathian WA Manager and simulation expert.

"Risk comes in the form of potential breakdowns and disruptions to operations, but, more importantly, risk comes in the form of missed opportunities which leave revenue on the table."

Simulation has become an essential component of the planning process for complex operations. In terms of both optimising current operations and feasibility studies for greenfield designs or upgrades to existing systems. But there is still a bit of road to travel to utilise simulation technology to its fullest capacity, especially in heavy industry. Mr Eustace said, "I have witnessed simulation being utilised too late in the system design process. In some cases, minor changes to the design could have provided significant performance improvements, and in others, the simulation model revealed that the design needed to be scrapped altogether. Additionally, failing to utilise the developed simulation models in the operational environment leads to missed process improvement opportunities that could have been easily identified."

Furthermore, missed opportunities arise when companies fail to include simulation models in their core logistics infrastructure. Forward-thinking companies put this type of IP asset in place before the immediate need for specific answers. A validated and trusted system model allows them to test and iterate rapidly through improvement ideas and upgrade pathways.

Michael noted that, "The most impact gained from simulation models is when clients maintain and upgrade their models according to their physical assets. The current models ensure companywide confidence, which allows the models to become integral parts of the planning process across the different planning horizons."

The resources sector was an early adopter of simulation to improve operations. Mining companies have been using simulation techniques since the 1990s after realising that they could view their logistics operations as manufacturing processes. This opened the door to simulation techniques initially designed to investigate queuing and congestion on assembly lines. Many Tier one miners now have internal simulation teams, making it intrinsic to their business processes. Additionally, operational simulation models are most effective when tightly coupled with the financial models of a business. In this way, revenue and cost are used to rank and compare infrastructure and operating control options. The simulation models then become the common link between the corporate and operational planning functions.

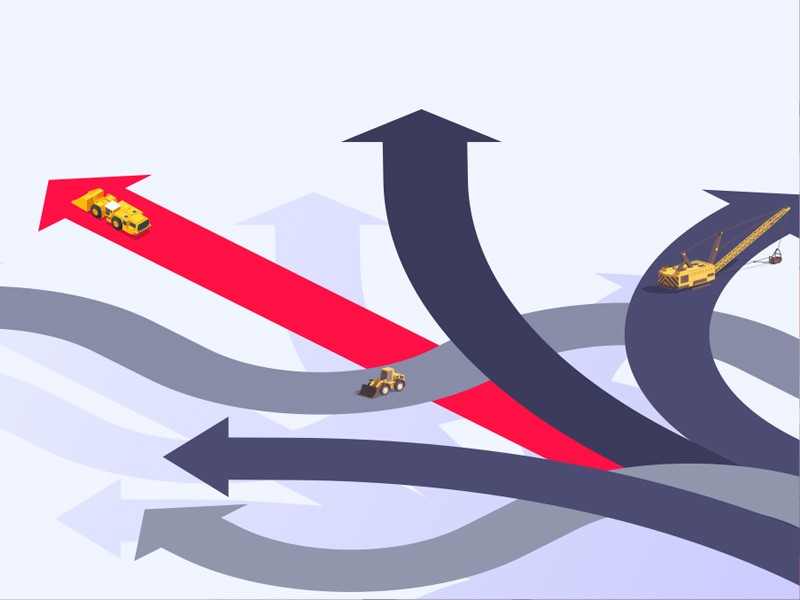

The major trend that we see at Polymathian is the combination of mathematical optimisation and simulation. The future of simulation is the improved integration of simulation models with real data and systems. This is enabled by cloud deployments and opens a host of new use cases for simulation models, bringing new relevance throughout the lifecycle of an industrial system. Better integration means that simulation models can leverage real-time and recent system data to replicate system performance, changing only that part of the system of interest. In contrast to the simulation reports gathering dust on a bookshelf, integrated models can be used for strategic analysis and forecast operational performance over the next shift, week or quarter. They can also be used to test the potential performance improvements that could be achieved with mathematical optimisation.

With the right approach and sound data, providing an accurate representation of the cause-and-effect interactions in a system is relatively easy to achieve and demonstrate with a simulation model. Many complex systems incorporate some degree of planning and scheduling, with associated decisions significantly influencing the system's performance. For these systems, mathematical optimisation is often combined with simulation to achieve a realistic representation of operational performance. Simulation can also be combined with optimisation to evaluate operational performance gains before deploying an optimisation tool.

The combination of technology can be applied either where simulation is used to quantify the benefit of an optimisation-based planning algorithm or where optimisation is embedded in the simulation decision logic to increase the model's accuracy. Both instances are delivering exciting benefits for our clients.

"Simulation will continue to evolve alongside, and together with, other techniques such as AI and machine learning. While there is a lot of buzz around these technologies, I believe that the most exciting advances will come when these analytics techniques are combined with simulation," said Michael Dallimore.

Meet Polymathian simulation experts and article contributors

Colin has been supporting the development and adoption of simulation and optimisation technology for the last twenty years. He has extensive subject matter knowledge in resource supply chain and bulk materials handling operations which he uses to identify process improvements for complex operations with rigorous quantitative and data-driven analysis. Connect with Colin on LinkedIn.

Michael Dallimore has extensive experience in iron ore, copper and bulk haulage sectors and has provided simulation and analytics solutions to most of the major mining houses both in Australia and internationally. Currently, Michael manages operations for Polymathian's Perth location. Connect with Mike on LinkedIn.